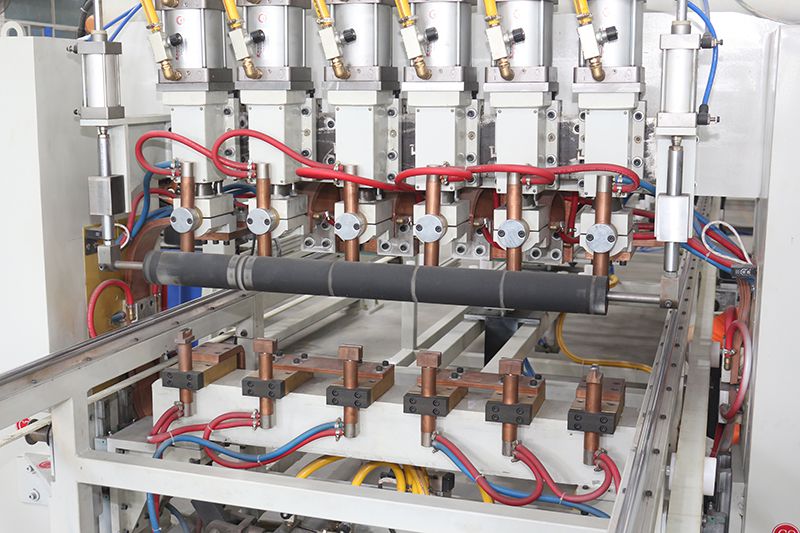

Welding robot is welding automation that utilizes a welding robot arm to weld, composed of a 6-axis robotic arm and welding system. The 6-axis robotic arm offers a wide range of motion and can be installed at various angles, improving the flexibility of the system. The robotic arm can be equipped with different types of welding guns and can be seamlessly integrated with various welding power sources from different brands. This versatility enables the system to meet diverse welding requirements and perform multiple welding processes effectively.

| Welder Type | Brand |

| MIG Welding Machine | OTC, Panasonic, BINGO, AOTAI |

| TIG Welding Machine | Panasonic, BINGO, AOTAI |

| Laser Welding Machine | MAX, Raycus |

If you have any business inquiries or product questions, please feel free to contact us.

With over 20 years of combined experience in the field of resistance welding machines and automatic welding systems, we know what global manufacturers need to stand out in their competitive market.

View All

With over two decades of expertise in the fabrication of welding machines and welding robots, we specialize in delivering industrial welding solutions tailored to diverse sectors, enabling automated welding and industrial robot welding applications.

In the realm of automatic welding and industrial robotic welding solutions, we transcend the role of a mere welding equipment manufacturer to function as a comprehensive weld system integrator.

View All