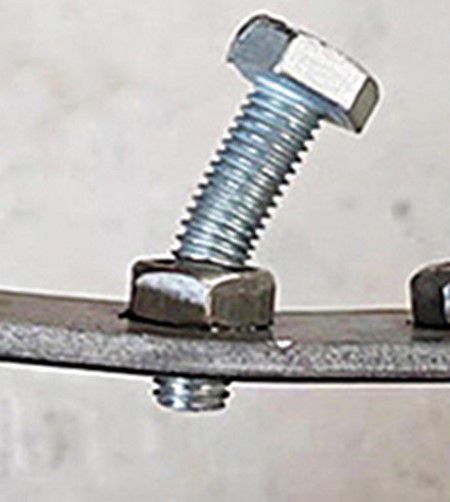

As one of the most common fastening methods, metal hardware is applied for numerous production processes. Since conventional threaded fasteners are often susceptible to loosening over time, welding for nut and bolt attachment is becoming a solution due to it provides strong bonds and welded joints are less prone to loosening caused by vibrations or movement.

As a resistance welding machine manufacturer, we offer a wide range of welding machines including spot welder, seam welder, projection welder and butt welder. We also assist customers in identifying an appropriate welding solution with options of power supplies to accommodate their production efficiency requirements. At our company, we go to great lengths to meet your production demands in relation to the production design and budget.

Ideal for automatic welding of nuts;

Automatic nuts loading, manual base parts loading and unloading;

Ideal for welding products requiring multi-position welding;

Welding head is adjustable;

Ideal for welding products requiring multi-position welding;

Vibratory feeder for large-sized nuts feeding;

X-Y axis traveling;

Automatic welding;

Automatic loading and welding of small parts;

Achieving continuous welding process with turntable;

Ideal for automatic production of lamp shade frame, accomplishing wire straightening, bending, cutting, automatic spot welding and automatic unloading of finished products;

Ideal for spot welding of compressors used in air conditioner and refrigerator;

Using high-power capacitor discharge power supply, ensuring strong and reliable welding;

When comes to sheet metal fabrication, joining metal components to form the desired shape is necessary after cutting them to required size. As a result, sheet metal welding is a crucial process of metal products manufacturing, typically sheet metal box.

There are numerous varieties of kitchen utensils, which are commonly made from stainless steel for its strong resistance to corrosion and cracking. Stainless steel welding requires specialized welding machines with stable performance.

In electrical applications, there are many types of electrical components and connections made from copper that offers a better electrical capacity. The solution for copper welding is becoming a common challenge faced by many electrical component manufacturers.

In the automotive industry, vehicle parts are required to be durable and must be assembled and joined with strong welds. So, automotive part welding is crucial in the automotive manufacturing market to ensure the safe operation of vehicles.

If you have any business inquiries or product questions, please feel free to contact us.