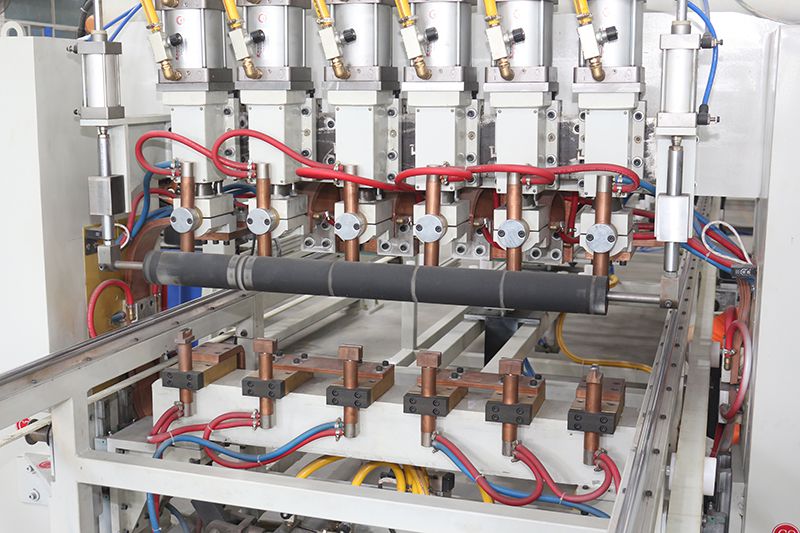

The AC pulse spot welder operates by utilizing standard mains electricity and employs a transformer to lower voltage while increasing current. This low-voltage, high-current output is directed to the joint of the workpieces through the electrodes. As a result of the resistance between the workpieces, high temperatures are generated, effectively heating the metal. This intense heat causes the workpiece to melt, facilitating the fusion of the workpieces together.

Various metal rods and wires, including tungsten, molybdenum, iron, nickel, carbon steel, and stainless steel.

Welding of iron wire products, hardware lighting fixtures, kitchen utensils, auto parts, metal hardware and more

For spot welding of metal sheets (copper, aluminum, stainless steel, galvanized steel)

For spot welding of metal sheets (copper, aluminum, stainless steel, galvanized steel) controlled by foot pedal, ideal for customers with lower budgets

| Model | Input Voltage (V) | Input Power (kVA) | Output Current (A) | Pressure Force (kg) | Electrode Stroke (mm) | Closure (mm) | Platform Distance (mm) | Electrode Distance (mm) | Cooling Water (Lit/Min) |

| | 220 | 10 | 5000 | 200 | 50 | 65-115 | - | 145-165 | - |

| | 220 | 10 | 6000 | 200 | 50 | 65-115 | - | 145-165 | - |

| | 220 | 10 | 8000 | 200 | 50 | 65-115 | - | 145-165 | - |

| | 380 | 16 | 10000 | 300 | 80 | - | - | - | 6 |

| | 25 | 12000 | 300 | 80 | - | - | - | 6 | |

| | 35 | 16000 | 350 | 80 | - | - | - | 6 | |

| WL-S-50K | 50 | 19500 | 500 | 80 | - | - | - | 6 | |

| | 25 | 12000 | 300 | 80 | 145-225 | 250 | 320-420 | 6 | |

| | 50 | 16000 | 350 | 80 | 145-225 | 250 | 320-420 | 6 | |

| | 50 | 19500 | 500 | 80 | 145-225 | 250 | 320-420 | 6 | |

| | 75 | 24000 | 1000 | 100 | 130-230 | 260 | 490-540 | 8 | |

| WL-SP-100K | 100 | 34000 | 1000 | 100 | 130-230 | 260 | 490-540 | 8 | |

| | 150 | 40000 | 1000 | 100 | 130-230 | 260 | 490-540 | 8 | |

| WL-SP-200K | 200 | 50000 | 1500 | 100 | 130-230 | 260 | 490-540 | 8 |

Optional touchscreen panel or digital button panel for setting welding parameters.

Thickened copper tape aims to enhance its conductivity.

Customized electrodes (can be tailored to different materials and products)

Arm length can be customized according to the product size.

If you have any business inquiries or product questions, please feel free to contact us.

With over 20 years of combined experience in the field of resistance welding machines and automatic welding systems, we know what global manufacturers need to stand out in their competitive market.

View All

With over two decades of expertise in the fabrication of welding machines and welding robots, we specialize in delivering industrial welding solutions tailored to diverse sectors, enabling automated welding and industrial robot welding applications.

In the realm of automatic welding and industrial robotic welding solutions, we transcend the role of a mere welding equipment manufacturer to function as a comprehensive weld system integrator.

View All