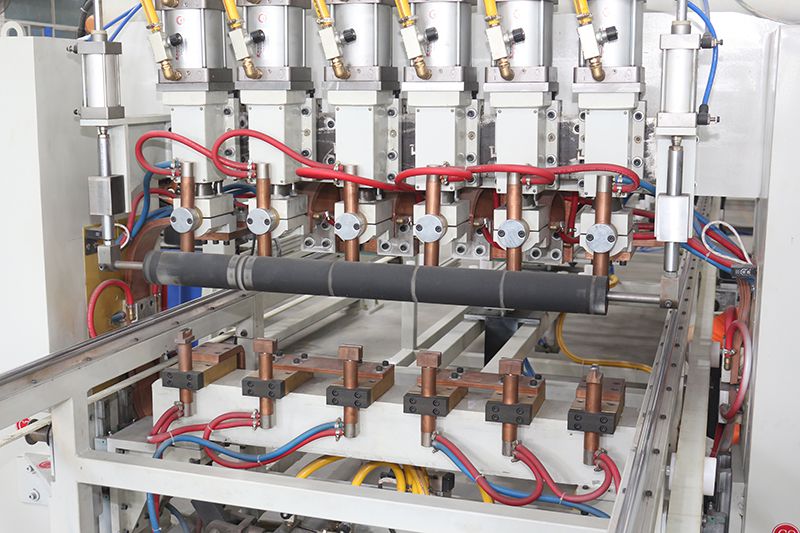

Resistance butt welding machine utilizes the electrical resistance between the contact surfaces of two workpieces. By applying low voltage and high current, the contact surfaces of the metal pieces are rapidly heated to the point of melting and then fused together. At Hwashi Technology, there are various types of butt welding machines available, including flash butt welding machine (AS), copper-aluminum welding machine, wire butt welding machine, automatic ring making and butt welding machine, and automatic bending and butt welding machine. The power supply can be either AC or mid-frequency DC.

Metal wires such as low carbon steel, copper, aluminum, and stainless steel

Welding of handicrafts, daily hardware, furniture, lighting, wire mesh, and more.

Applicable wire size: 1mm-12mm

For T-shaped joint butt welding of reinforcing bars inside square wire

For automatic bending and butt welding of square wire frame

For automatic ring making and butt welding of round wire

| Model | | | |

| Power Supply | Single phase 380V±10% | ||

| Rated Capacity | 150kVA | 100kVA | 75kVA |

| Duty Cycle | 25% | ||

| Max. Secondary No-Load Voltage | AC11.8V | AC8.7V | AC7.2V |

| Max. Secondary Short Circuit Current | 28KA | 26KA | 23KA |

| Welding Specifications | 16 sets | ||

Optional in cost-effective AC power supply or stable and energy-saving mid-frequency power supply.

Allows for welding products with different wire diameters.

Allows for automatic ring making and butt welding, automatic wire butt welding, saving labor

Ensures welding different products, such as round wire, square wire, solid or hollow pipes, keys, etc.

If you have any business inquiries or product questions, please feel free to contact us.

With over 20 years of combined experience in the field of resistance welding machines and automatic welding systems, we know what global manufacturers need to stand out in their competitive market.

View All

With over two decades of expertise in the fabrication of welding machines and welding robots, we specialize in delivering industrial welding solutions tailored to diverse sectors, enabling automated welding and industrial robot welding applications.

In the realm of automatic welding and industrial robotic welding solutions, we transcend the role of a mere welding equipment manufacturer to function as a comprehensive weld system integrator.

View All