Seam welding is a resistance welding process for joining metal sheets in continuous, leak tight seam joints by directly applying opposing forces with electrodes consisting of rotary wheels. The seam of the resistance seam welding machine consists of individual weld spots. The formation process of each weld spot involves three stages: pressure application, heating and melting, and cooling and crystallization, similar to spot welding. However, there are significant differences between seam welding and spot welding. Due to the inevitable occurrence of diversion, the distribution of the electrical and thermal fields in the welding area possesses its own characteristics. The rotary wheel of the seam welder continuously rotates to change the welding position during the application of pressure and electric heating, and as a result, the distribution of the electrical and thermal fields and the crystallization characteristics of the molten zone are all related to the speed of position change.

Products requiring sealed welding, such as welding temperature controllers, battery nickel sheets, oil-filled radiators, power capacitors, car shock absorbers, bicycle wheel rims, fryer baskets, water pumps, and can and barrel manufacturing.

For seam welding of metal sheets (copper, aluminum, stainless steel, galvanized steel)

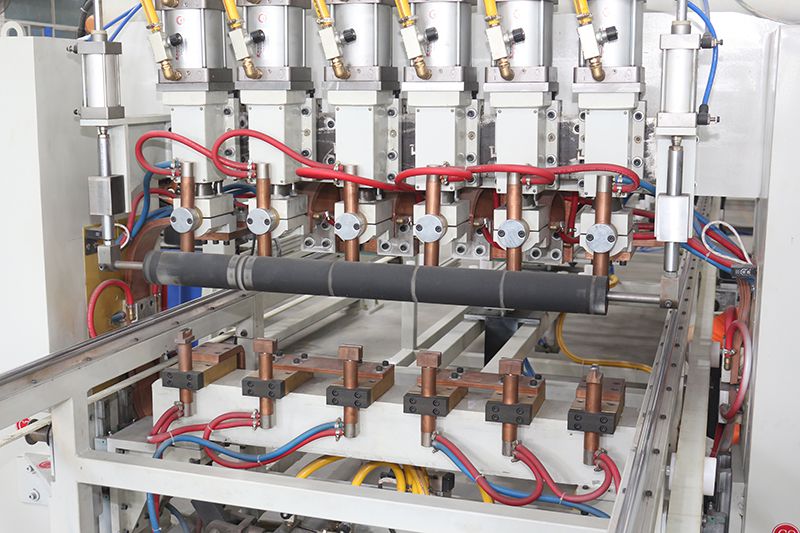

For automatic longitudinal seam welding and straight seam welding of cylindrical thin sheets

| Model | | |

| Power Supply | Three phase 380V±10% | Single phase 380V±10% |

| Rated Capacity | 250kVA | 300kVA |

| Welding Specifications | 32 sets | 16 sets |

| Diameter of Upper Electrode Wheel | 200mm | |

| Diameter of Lower Electrode Wheel | 200mm | |

| Electrode Wheel Width | 5mm | |

| Speed | 0-800mm/min (stepless adjustable) | |

| Distance Between Electrode Wheels | 50mm | |

| Throat Depth | 500mm | |

| Drive Method | Upper Electrode Wheel Drive (simultaneous drive with upper and lower wheels is customizable) | |

Optional in cost-effective AC power supply or stable and energy-saving mid-frequency power supply.

Drive provided on top or bottom roller electrode as required, facilitating ease of use.

For straight seam welding

For circular seam welding

If you have any business inquiries or product questions, please feel free to contact us.

With over 20 years of combined experience in the field of resistance welding machines and automatic welding systems, we know what global manufacturers need to stand out in their competitive market.

View All

With over two decades of expertise in the fabrication of welding machines and welding robots, we specialize in delivering industrial welding solutions tailored to diverse sectors, enabling automated welding and industrial robot welding applications.

In the realm of automatic welding and industrial robotic welding solutions, we transcend the role of a mere welding equipment manufacturer to function as a comprehensive weld system integrator.

View All