Capacitor discharge spot welding machine, also referred as capacitive discharge or CD welding, stores energy from a capacitors bank which on discharging, release the current by very fast pulse. In comparison to other welding methods such as AC spot welding, it has a lower instantaneous power demand from the grid, balanced load among phases, high power factor, and the ability to provide concentrated energy to the welding area. As a result, it produces weldments with excellent surface quality and minimal deformation. This makes it suitable for welding difficult-to-weld non-ferrous metals with good thermal and electrical conductivity, and particularly ideal for stainless steel products and products with high requirements for the welding surface.

Stainless steel, silver, and other alloy materials.

Industrial production and manufacturing:

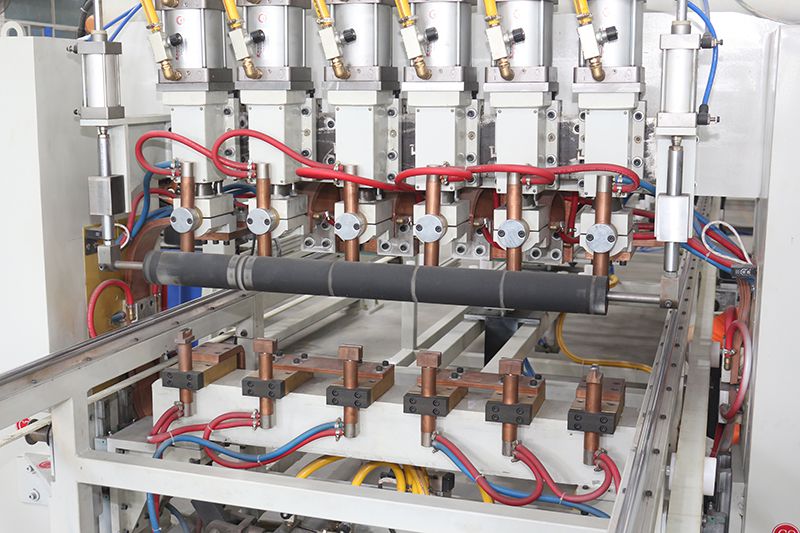

such as welding of stainless steel cookware handles, cooking pot handles, stainless steel strips, battery welding, and electronic components soldering.

For welding small hardware and parts, such as batteries, heating wires, and other similar components

For welding stainless steel cookware, suitable for a variety of products without the need for frequent mold changes

| Model | Input Voltage | Input Power | Output Power | Capacitance | Electrode Force | Electrode Stroke |

| | 380V | 1kVA | 300J | 3000uF | 30kg | 25mm |

| | 380V | 2kVA | 500J | 4500uF | 100kg | 50mm |

| | 380V | 2.5kVA | 1000J | 9000uF | 100kg | 50mm |

| | 380V | 3kVA | 1500J | 14000uF | 350kg | 80mm |

| | 380V | 5kVA | 3000J | 28000uF | 350kg | 80mm |

| | 380V | 7kVA | 4500J | 42000uF | 800kg | 100mm |

| | 380V | 10kVA | 6000J | 60000uF | 1000kg | 100mm |

| | 380V | 12kVA | 7000J | 70000uF | 1000kg | 100mm |

| | 380V | 15kVA | 8000J | 80000uF | 1000kg | 100mm |

| | 380V | 20kVA | 15000J | 150000uF | 1500kg | 100mm |

| | 380V | 25kVA | 18000J | 180000uF | 2000kg | 100mm |

| | 380V | 30kVA | 20000J | 200000uF | 2000kg | 100mm |

| | 380V | 40kVA | 25000J | 250000uF | 2000kg | 100mm |

| | 380V | 50kVA | 30000J | 300000uF | 2000kg | 100mm |

| | 380V | 60kVA | 35000J | 350000uF | 2000kg | 100mm |

Selectable options include DIP switch control panel, touch screen panel, or digital button panel for setting welding parameters.

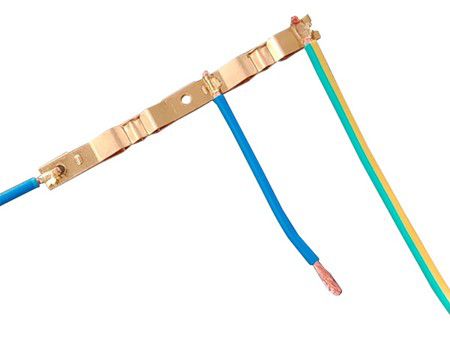

Thickened copper tape aims to enhance its conductivity.

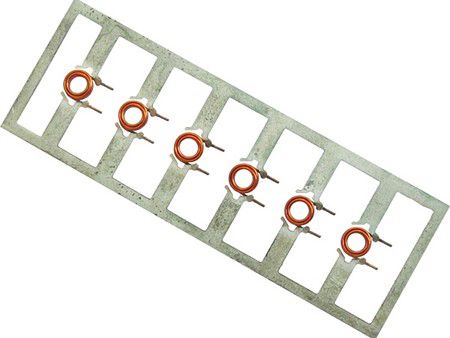

Customized electrodes (can be tailored to different materials and products)

Arm length can be customized according to the product size.

If you have any business inquiries or product questions, please feel free to contact us.

With over 20 years of combined experience in the field of resistance welding machines and automatic welding systems, we know what global manufacturers need to stand out in their competitive market.

View All

With over two decades of expertise in the fabrication of welding machines and welding robots, we specialize in delivering industrial welding solutions tailored to diverse sectors, enabling automated welding and industrial robot welding applications.

In the realm of automatic welding and industrial robotic welding solutions, we transcend the role of a mere welding equipment manufacturer to function as a comprehensive weld system integrator.

View All